AS High Efficiency Pump

AS series represents the next-generation high-effiency pump, exceeding industry benchmark by 3-8%.

| Outlet diameter | 80 ~ 1600 mm |

| Capacity | ≤14000 m³/h |

| Head | 10 ~ 240 m |

| Operating temperature | ≤ 105 ℃ |

| Working pressure | Up to 3 MPa |

AS series high-efficiency energy-saving pump is a new generation of high-efficiency horizontal centrifugal pump developed by our company in cooperation with Xihua University for many years. In response to the current energy-saving market demand, it is integrated with the advantages of the same type of centrifugal pumps produced by well-known domestic and foreign manufacturers. AS pump concentrated use of the current advanced ternary flow design theory, computer fluid simulation technology (cfl), computer finite element analysis technology (CAE).

The efficiency exceeds the world's leading level, and has many advantages such as excellent structure, smooth operation, low noise, and easy to maintenance. It is widely used in the power industry, water conservancy industry, steel industry, petrochemical industry, water plant projects, municipal engineering, sewage treatment, Shipbuilding industry, mineral exploration and mining, aviation industry and other occasions.

Main performance parameters

Pump outlet diameter DN:80--1100MM

Capacity Q:Max 20000m3/h

Head H:Max 320m

Pressure P:Max 4MPa

Temperature T: Max 105℃

Description of Pump Type

For example: AS300-640-J-A

AS: high efficiency single stage double suction split centrifugal pump

300: pump outlet diameter(mm)

640: impeller normal diameter(MM)

J: Pump speed changed(Maintain the speed without mark)

A: Changed outer diameter of impeller (the max diameter without mark, B cut the second C is the third time )

Pump material

Casing cast iron, ductile iron, cast steel

impeller cast iron, ductile iron, cast steel, bronze, stainless steel

shaft 45# steel、40Cr、3Crl3\35CrMo

shaft sleeve Q235A 304

wear ring Q235A,bronze,duplex SS

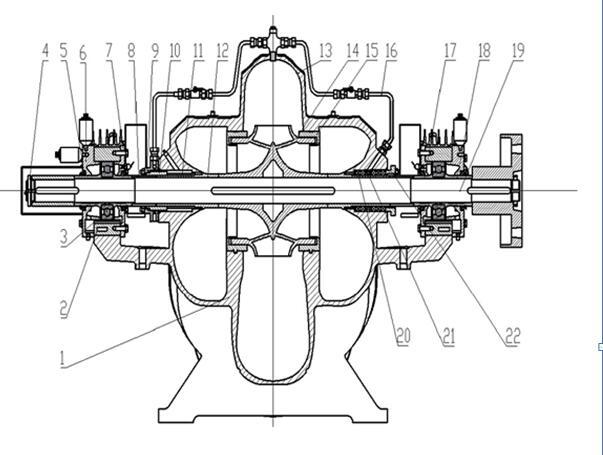

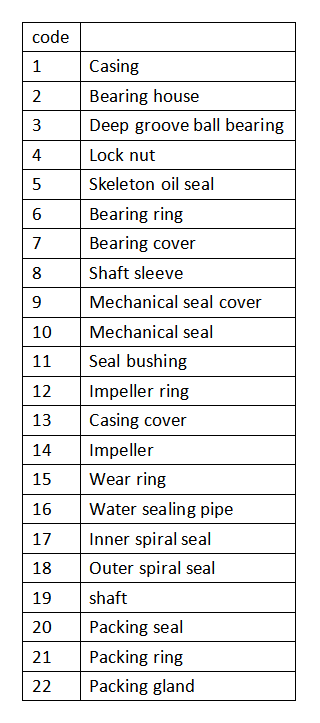

Construction Drawing

|

|

1.The shape of the AS high-efficiency energy-saving pump is designed by a professional shape design company according to the requirements of modern industrial aesthetics,Overall beauty。At the same time, according to the CAE mechanical simulation report, the local thickening increases the safety and reliability of the pump casing.

2.The AS high-efficiency energy-saving pump retains the characteristics of the mid-open pump that can be repaired directly by opening the pump cover and the characteristic of the double suction impeller automatically balancing the axial force,At the same time set the import and export on the same horizontal axis,It is conducive to engineering installation and pipeline design and layout.

3.The shaft of the AS high-efficiency energy-saving pump adopts a double shaft extension structure, and there is no difference between the forward and reverse shafts,Except for the key groove of the impeller, no other key groove, snap ring groove and step are provided in the middle section of the shaft,and it is one grade thicker than similar pump shafts, which enhances the life and strength of the shaft

4.The impeller and double-suction sealing ring of the AS high-efficiency and energy-saving pump adopt the double-sided seal of our company patent number ZL2013 2 0499236.5,The length of the leaked water is increased, the amount of leakage is reduced, and the speed of the leaked water can be used to improve the efficiency.

5.The impeller and impeller bushing of the AS high-efficiency energy-saving pump are sealed with a copper pad, which is durable and extends the service life. A short shaft sleeve and an O-ring are added behind the impeller stop sleeve to achieve double axial and radial sealing. When installing the mechanical seal, put the outer snap ring on the positioning slot 1 to make the mechanical seal installation more convenient; After the mechanical seal is installed, the outer snap ring is retracted onto the clamping slot 2, so that the mechanical seal flushing cooling water can better flush and cool the mechanical seal.

6.The shaft seal structure of the AS high-efficiency energy-saving pump is reliable and universal. It can be used as a container box structure, but also suitable for packing or mechanical seal, fully considering the versatility and interchangeability. Fully taking into account the excellent environment and applicable life requirements of various types of shaft seals.

7.The bearing body of the AS high-efficiency energy-saving pump adopts a cylindrical structure, which is stable and reliable; It can be equipped with temperature measuring element, vibration measuring element and constant oil cup at the same time; In terms of cooling, it can be cooled by circulating water, or it can be freely cooled by fins.

8.The bearing body seal of the AS high-efficiency energy-saving pump adopts the double seal of the thread seal box skeleton oil seal,It has been tested and verified that the protection level is equivalent to the IP55 of the motor and can be operated outdoors.

9.AS high-efficiency energy-saving pump adopts clearance fit between bearing and shaft,When the bushing presses the bearing, the outer ring of the O-ring squeezes and deforms, and the entire structure becomes a tight fit. After the sleeve nut is loosened, the elasticity of the O-ring springs the sleeve away,No special disassembly and assembly tools and space are required, saving workload.

10.The bearing bracket of AS high-efficiency energy-saving pump adopts our company's patent number ZL 2013 2 0373133.4 oblique overflow groove, When debris blocks the drain hole, water can still flow out of the overflow tank, It overcomes the disadvantage that the packing water may soak the bearing and achieves the purpose of protecting the bearing.

11.The bearing body of the AS high efficiency energy-saving pump is fixed on the pump body through the bearing body pressure block,Easy to disassemble, strong interchangeability, stable and reliable.

12.A beautiful and elegant protective cover is installed between the bearing body and the shaft seal of the AS high-efficiency energy-saving pump. Ensure the safety of on-site operators and inspection personnel.

13.AS high-efficiency energy-saving pumps are tightly secured with round nuts and stop washers in the axial direction,Prevent axial movement and loosening of sleeve parts; It can also prevent the pump from loosening rotor components due to short-term reversal.

Advisory Message

To: Hunan M&W Pump Co., Ltd