XS Horizontal Split Case Pump

Resembling the KSB Omega pump, XS series has wide range of applications including municipal water, HVAC, power plant, mining etc.

| Outlet diameter | 80 ~ 2,200 mm |

| Capacity | 22 ~ 25,000 m³/h |

| Head | 7 ~ 280 m |

| Operating temperature | -20 ~ 200°C |

| Working pressure | ≤ 5 mPa |

OVERVIEW

XS type pump is a new generation of high performance single-stage double-suction centrifugal split pumps. They are mainly used in delivering liquids of the water plant, air conditioner circulation water, heating pipe network system, building water supply, irrigation and drainage of pump stations, power plants, industrial water supply system, fire protection, ships industry and mine. It is a new substitute for SH, S, SA, SLA and SAP.

DESIGNATION KEY

Example: XS250-450A-L(R)-J

XS - Horizontal split case pump

250 - Discharge nozzle diameter (mm)

450 - Nominal impeller diameter (mm)

A - Changed outer diameter of impeller (Absence indicates nominal diameter)

L - Vertical mount

R - Heating water

J - Changed pump speed (Absence indicates nominal speed)

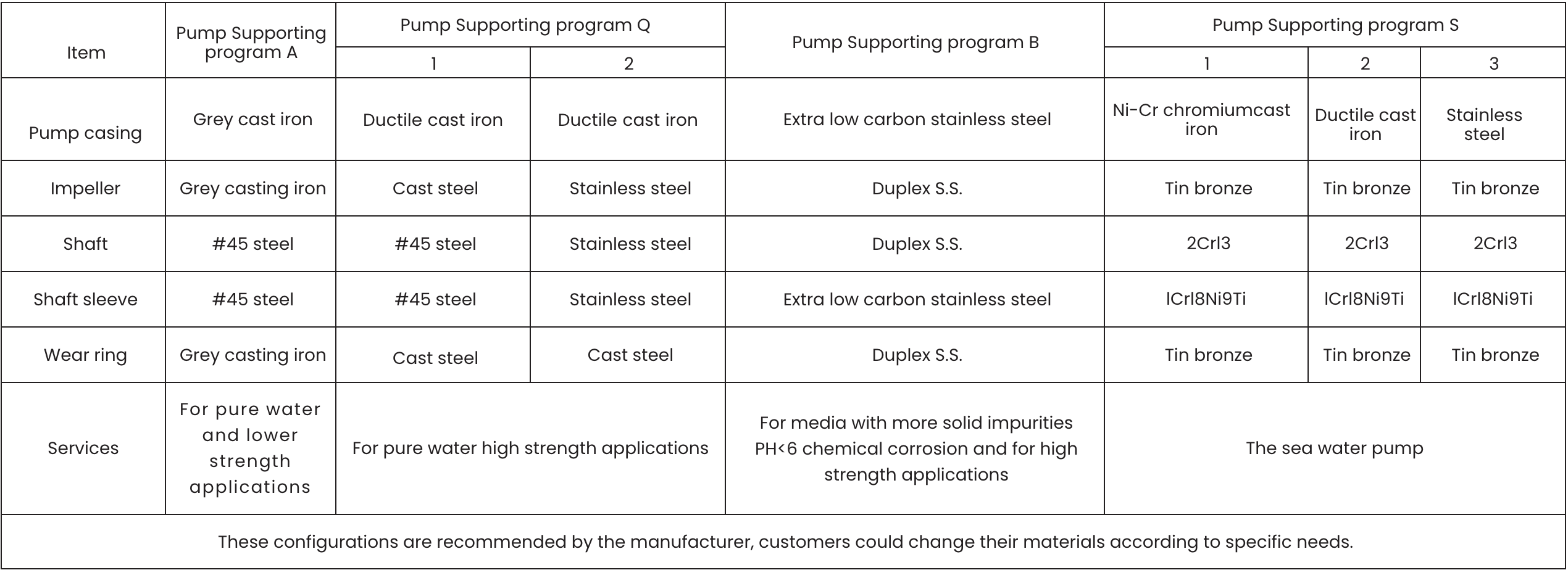

MATERIALS

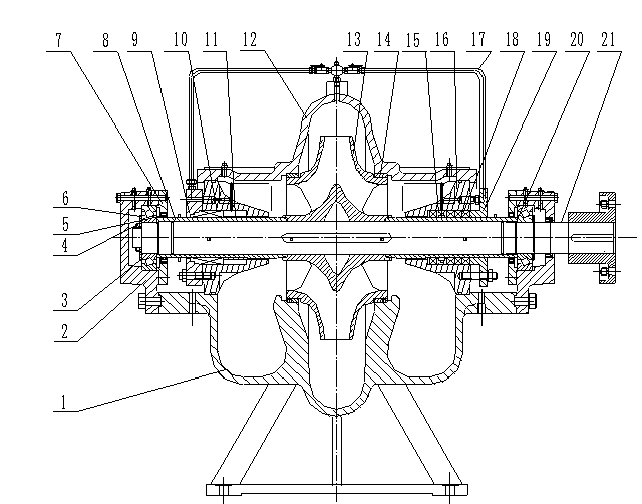

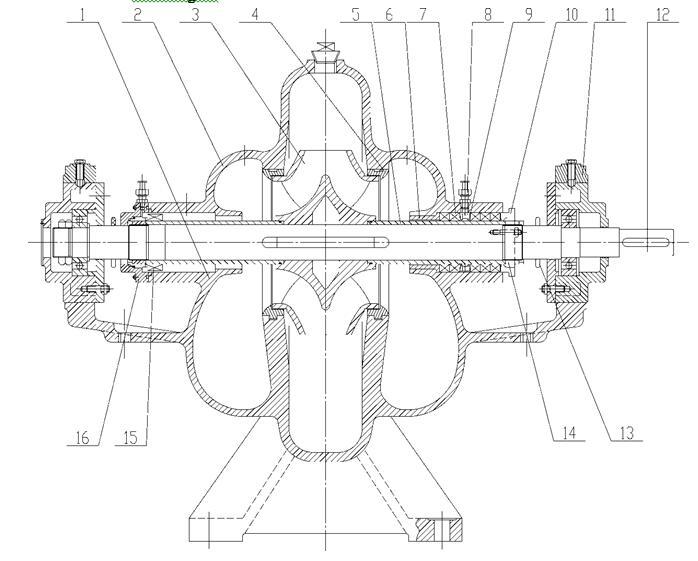

CONSTRUCTION DRAWING I

|  |

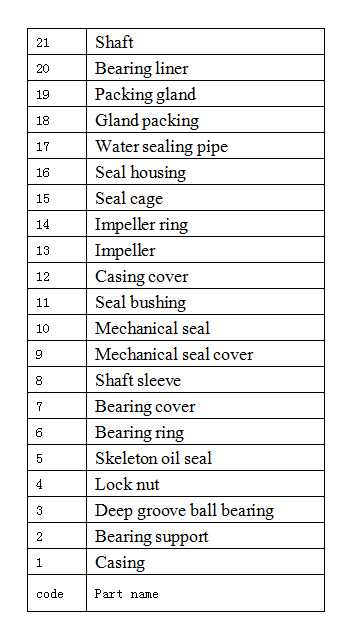

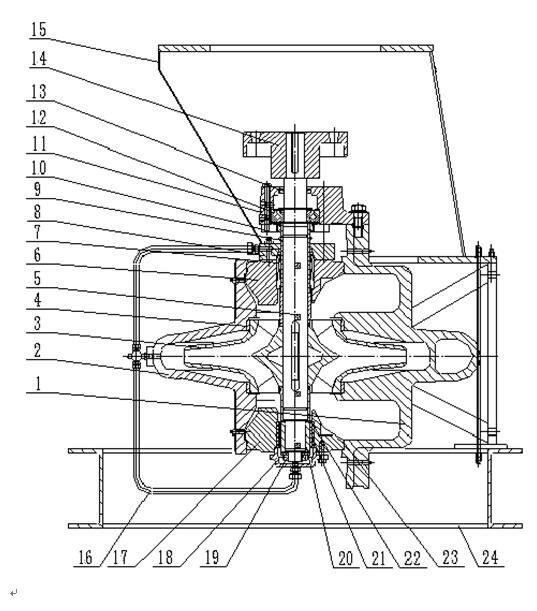

CONSTRUCTION DRAWING II

|  |

XS-L VERTICAL STRUCTURE

|  |

- Cost-efficiency: Advanced hydraulic models deliver 2-3% higher efficiency than comparable pumps.

- Enhanced operational stability: Shortened bearing span reduces vibration/noise, enables speed adjustment for broader application scenarios while maintaining reliability.

- Infrastructure cost reduction: 1-3m lower NPSH requirement decreases civil engineering complexity and extends equipment service life.

- High-temperature resilience: Mid-frame support, reinforced casing, sealed cooling, and oil-lubricated bearings ensure stable operation up to 200°C, meeting district heating system demands.

- Customized durability: Top-grade bearing is adopted with user-specified part material to withstand diverse operational environments, minimizing maintenance expenses.

- Operational safety: Rotor can be operated in reverse to avoid water hammer and pump damage

- Simplified installation and maintenance: The inlet and outlet are set on the same horizontal axis, conducive to engineering installation and piping layout Non-adjustable mechanical seal design enables tool-free replacement, minimizing downtime. Elastic prestress design is utilized to simplify rotor installation and dismounting without gap adjustments.