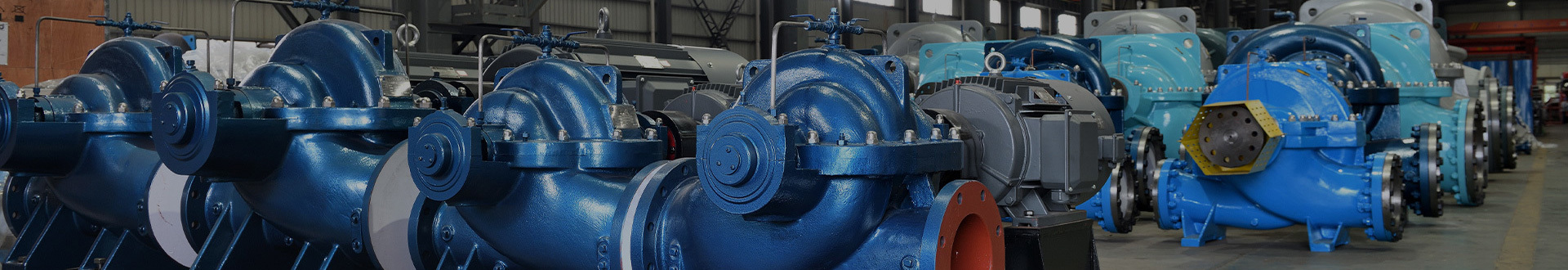

DS Multi-Stage Split Case Pump

DS series offers an extended high-efficiency operating range, ideal for long-distance water transport, oil pipeline, power plant, mining, seawater desalination, etc.

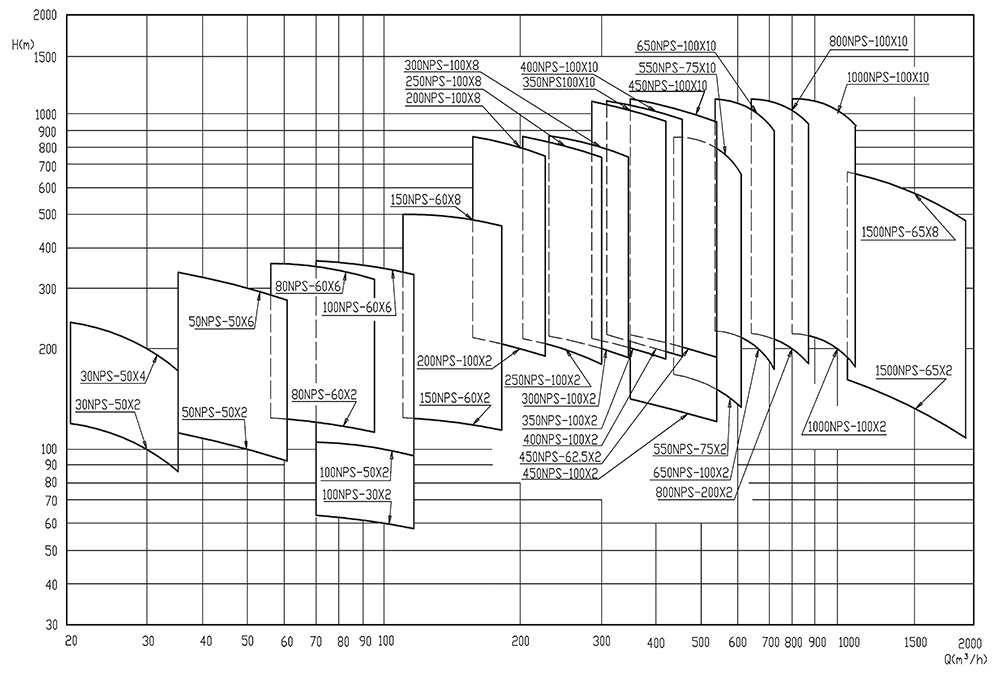

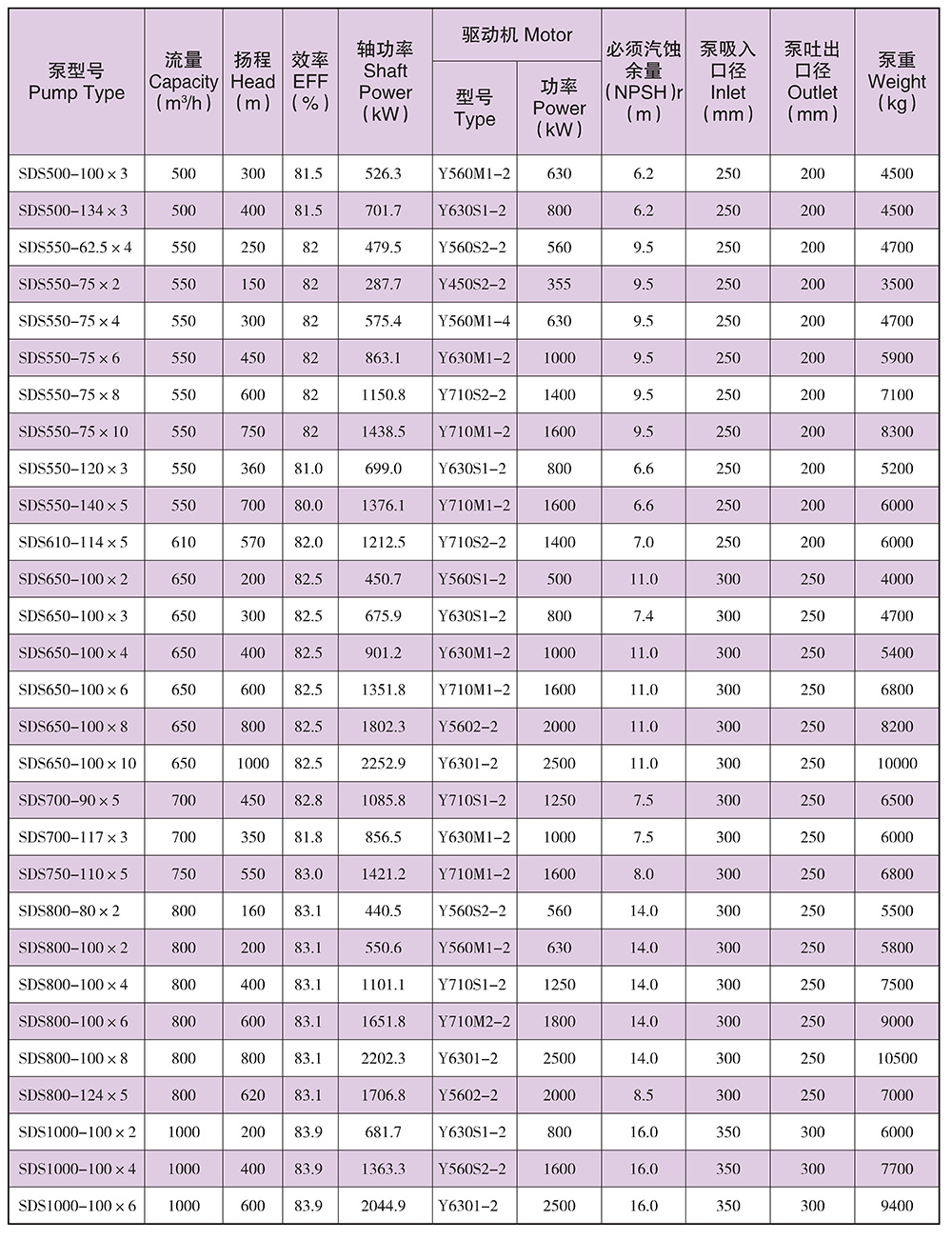

| Outlet diameter | 80 ~ 1,600 mm |

| Capacity | 100 ~ 6,000 m³/h |

| Head | 100 ~ 1,100 m |

| Operating temperature | -20 ~ 200 ℃ |

| Working pressure | ≤ 20 mPa |

OVERVIEW

The DS/DK series employs CFD and FEA simulation to deliver energy-efficient performance across water conservancy, petrochemical, power generation, and municipal applications. Key features include an extended high-efficiency operating range, reduced NPSHr, enhanced operational stability, simplified maintenance protocols, and advanced shaft sealing technology.

DESIGNATION KEY

Example: 200DK-55X4

DK - Multistage split case pump

200 - Discharge nozzle diameter (mm)

55 - Nominal impeller diameter (mm)

4 - Stages of impeller

MATERIALS

部件 Part | 配套方案 A Material Variant A | 配套方案 Q Material Variant Q | 配套方案 B Material Variant B | 配套方案 C Material Variant C | |||

1 | 2 | 1 | 2 | 3 | |||

泵壳 Pump casing | 灰铸铁 Grey cast iron | 球墨铸铁 Ductile cast iron | 球墨铸铁 Ductile cast iron | 超低碳不锈钢 Extra low carbon stainless steel | HT250Ni2Cr | 316L | 双相不锈钢 Duplex stainless steel |

叶轮 Impeller | 灰铸铁 Grey casting iron | 铸钢 Cast steel | 不锈钢 Stainless steel | 双相不锈钢 Duplex stainless steel | 316L | 316L | 双相不锈钢 Duplex stainless steel |

主轴 Shaft | 45号钢 #45 steel | 45号钢 #45 steel | 不锈钢 Stainless steel | 双相不锈钢 Duplex stainless steel | 35CrMo | 3Cr13 | 2Cr13 |

轴套 Shaft sleeve | 45号钢 #45 steel | 45号钢 #45 steel | 不锈钢 Stainless steel | 超低碳不锈钢 Extra low carbon stainless steel | 316 | 316L | 316L |

密封环 Wear ring | 灰铸铁 Grey casting iron | 铸钢 Cast steel | 铸钢 Cast steel | 双相不锈钢 Duplex stainless steel | Copper alloy | 316L | 316L |

适用场景 Applications | 适用于普通清水,以及低强度要求 For clear water and less demanding applications | 适用于普通清水,以及更高强度要求 For clear water and more demanding applications | 适用于含一定量颗粒杂质 的P H<6的 其它腐蚀性介质,以及更高强度要求 For corrosive fluid with PH<6 containing solid impurities, or other demanding applications | 用于新鲜海水取水泵,压力小于2.0MPa | 用于海水加压,压力在2.0-6.3MPa之间 | 用于对耐腐蚀要求更高,压力大于6.3MPa的场合 | |

说明:这些配置为公司推荐使用,客户可根据本身具体需求进行材质搭配 These configurations are recommended by the manufacturer. Customers may change materials according to specific needs. | |||||||

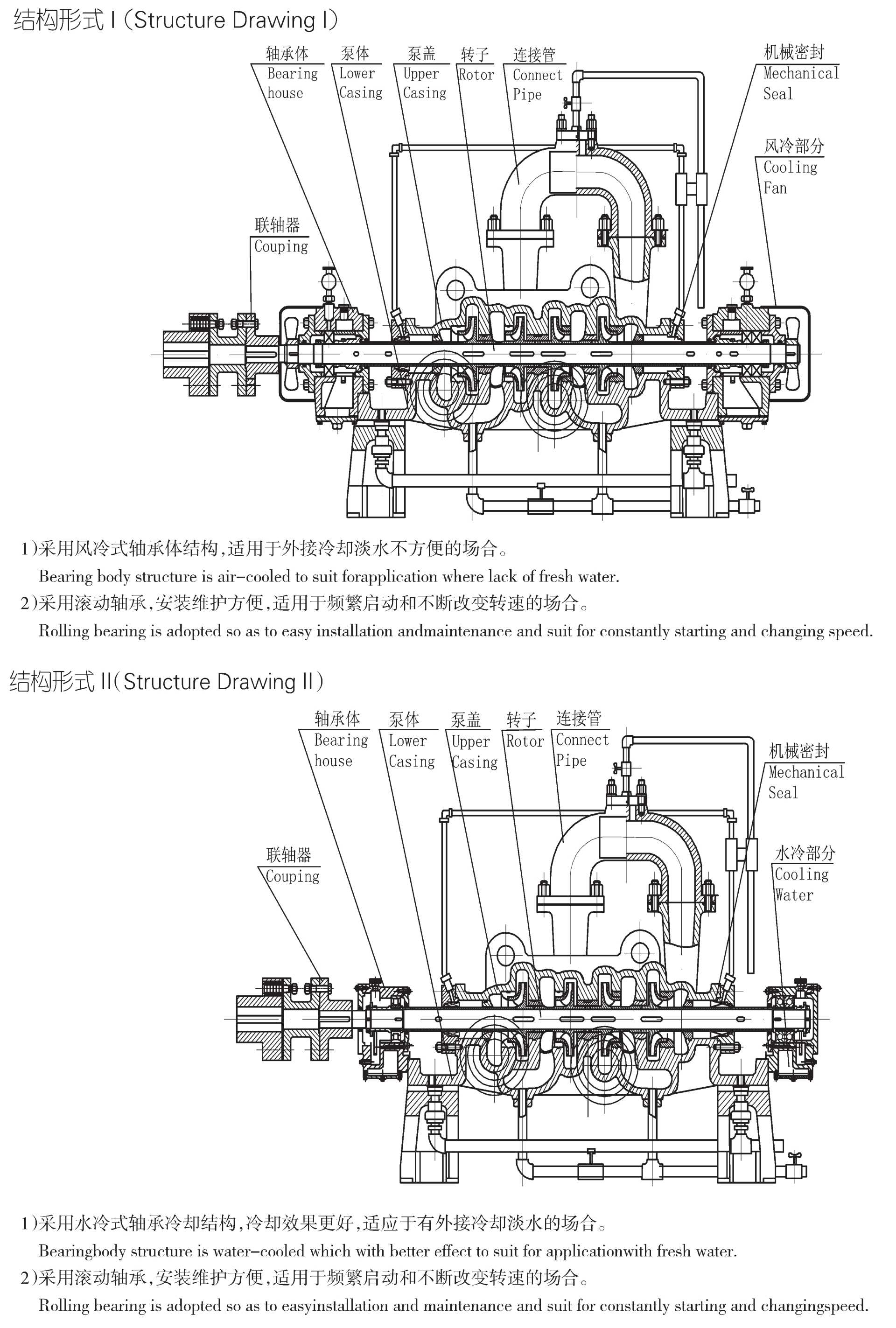

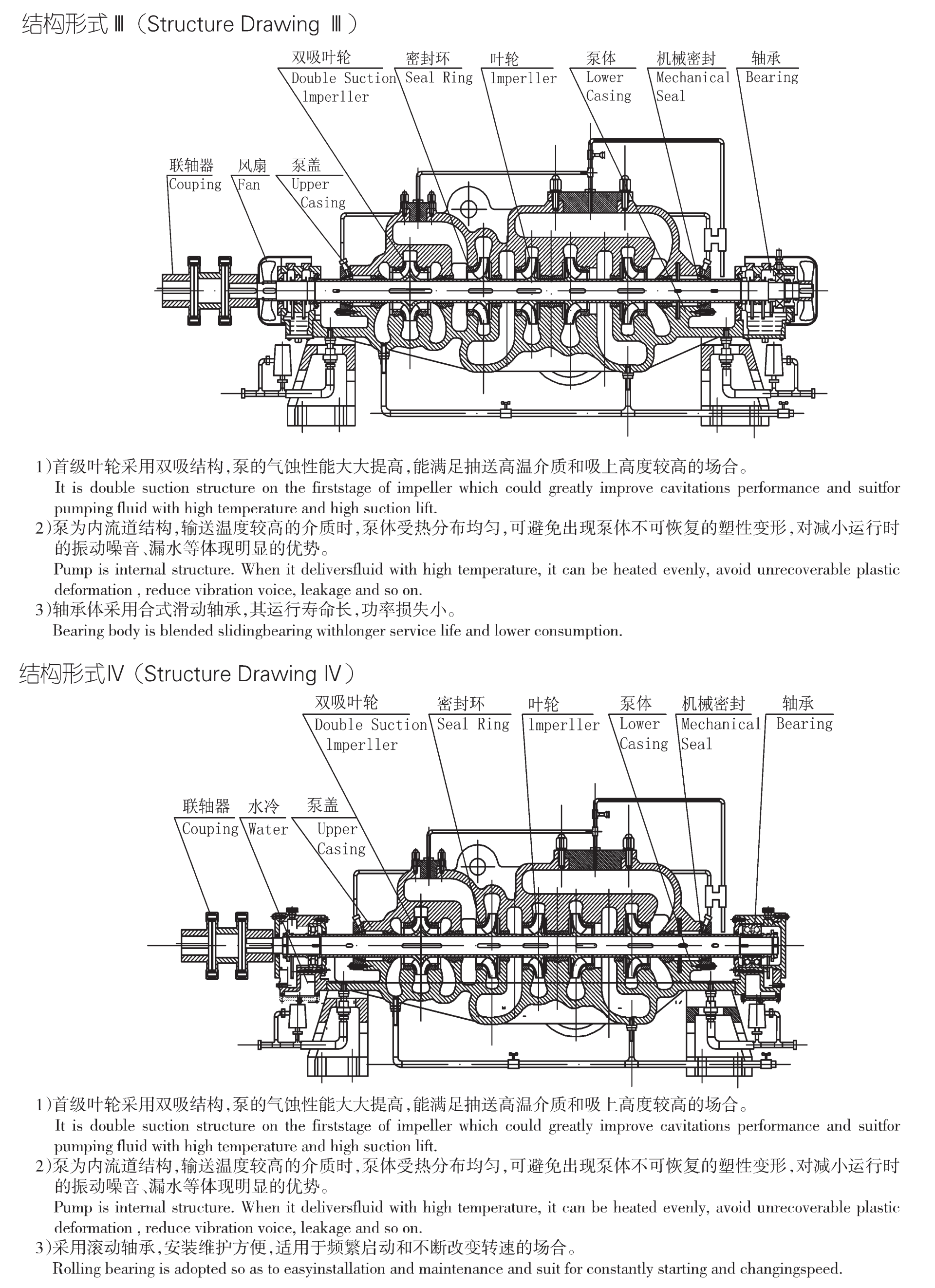

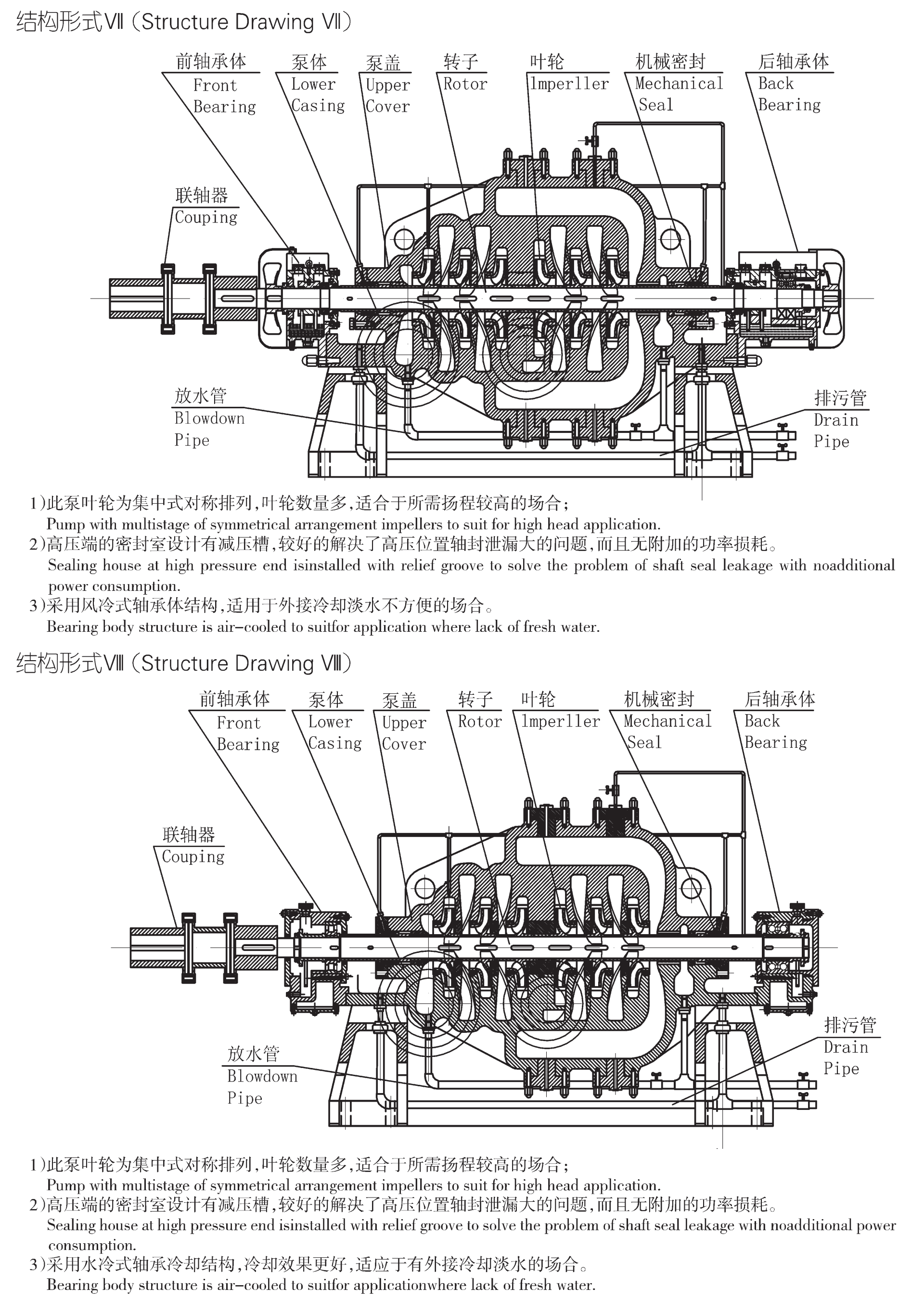

CONSTRUCTION DRAWING

- Optimized self-balancing structure: The outlets of each volute casing are arranged in 180° staggered symmetry to balance radial forces; the impellers at all stages are axially symmetrically or back-to-back arranged to balance axial forces; the main shaft is reinforced through computer-optimized design and experimental verification; the keys of each impeller are symmetrically positioned at 180° to balance partial radial deflection; the rotor assembly undergoes dynamic balancing testing to eliminate unbalanced mass; the transmission components utilize flexible pin-type couplings to balance radial forces generated during power transmission.

- Enhanced product efficiency: Specialized sealing design between suction chamber and discharge chamber minimizes volumetric loss due to interstage leakage, improving operating efficiency while extending maintenance intervals.

- Adaptable lubrication: Specialized bearing cooling/lubrication systems accommodate diverse operational environments.

- Compact design: Comprising casing, impeller, shaft, bearing house and couplings etc, the pump achieves optimized structure by reducing unnecessary balancing components to minimize footprint

- Seal reliability: The shaft seal is placed in the low pressure zone of the pump casing to extend service life and reduce mechanical seal failure risk.

- Rapid maintenance: Side-mounted pump inlet and outlet allow pump cover removal for servicing without detaching motors or pipelines.