High-efficiency booster pump

AS series represents the next-generation high-efficiency pump, exceeding industry benchmark by 3-8%.

| Outlet diameter | 80 ~ 1,600 mm |

| Capacity | ≤ 14,000 m³/h |

| Head | 10 ~ 240 m |

| Operating temperature | -20 ~ 200°C |

| Working pressure | ≤ 5 mPa |

OVERVIEW

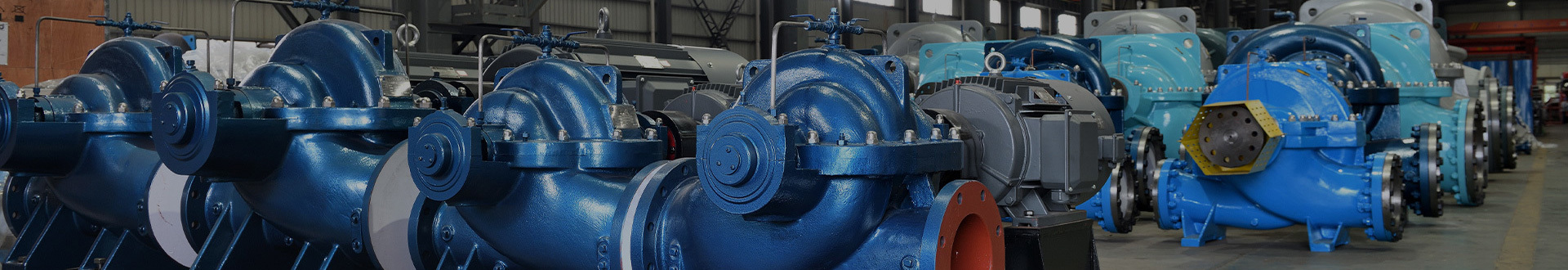

The AS series represents a next-generation high-efficiency centrifugal pump co-developed by our company and leading universities through years of R&D. Designed to address growing demand for energy-efficient solutions, this series integrates advanced technologies from world-renowned pump manufacturers. It achieves superior performance through optimized hydraulic design and innovative manufacturing processes.

DESIGNATION KEY

Example: AS300-640-J-A

AS - High efficiency single stage double suction centrifugal pump

300 - Discharge nozzle diameter (mm)

640 - Nominal impeller diameter (mm)

J - Changed pump speed (Absence indicates nominal speed)

A - Changed outer diameter of impeller (Absence indicates nominal diameter)

MATERIALS

Casing: cast iron, ductile iron, cast steel

Impeller: cast iron, ductile iron, cast steel, bronze, stainless steel

Shaft: 45# steel、40Cr、3Crl3\35CrMo

Shaft sleeve: Q235A 304

Wear ring: Q235A, bronze, duplex SS

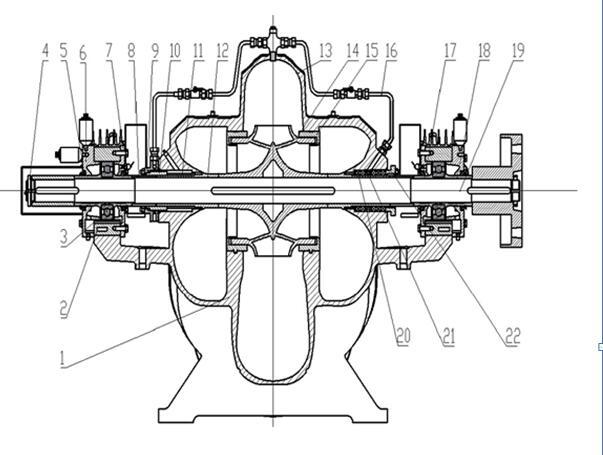

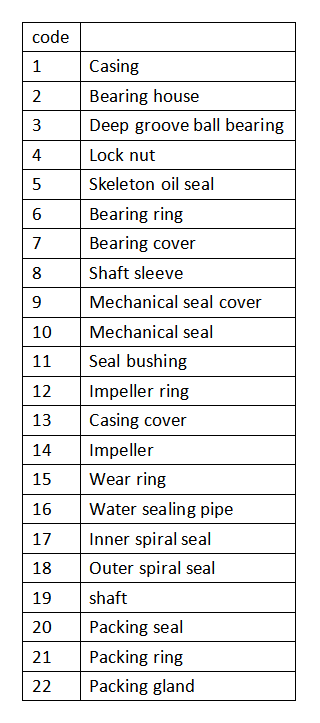

CONSTRUCTION DRAWINGS

|  |

- Superior energy savings: Incorporating 6 national patents, this innovative design delivers world-leading efficiency as certified by national authority.

- Enhanced flow efficiency: CFD-optimized hydraulic model is utilized to minimize vortex formation and hydraulic loss through smooth flow passages.

- Operation safety: Critical components are reinforced based on fluid dynamics analysis to enhance pump casing reliability, while the bearing house adopts cylinder structure to maintain structural stability

- Enhanced shaft durability: Reinforced shaft design eliminates keyways & grooves through FEA optimization, increasing strength and lifespan compared to standard pumps.

- Simplified installation and maintenance: The inlet and outlet are set on the same horizontal axis, conducive to engineering installation and piping layout. Split-case structure enables full pump repair through casing disassembly only.

- Configuration flexibility: The pump can be equipped with temperature/vibration senor and constant level oiler as required. Lubrication can be done with grease or thin oil. External water cooling is also configurable.