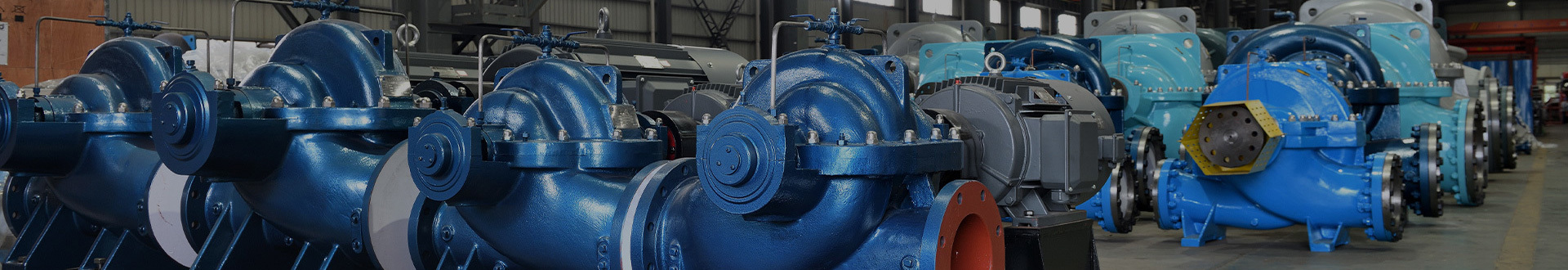

Submersible sewage pump is one of the commonly used pumps in sewage pump series products, because it does not need to build another pump room, QW submersible sewage pump series products only need to connect the outlet pipe to hang the pump into the pool and power on. Put into use, the large-flow and heavy-weight submersible sewage pump can be selected for coupling installation, which is also very convenient for maintenance and maintenance. It only needs to fix the coupling device at the bottom of the pool, and the pump with the coupler slides down to the bottom of the pool automatically along the guide rail of the coupler It can be put into use when it is automatically matched with the outlet flange of the coupling device. The WQ (QW) type non-clogging submersible sewage pump is the first in the industry to introduce the advanced technology of the Federal German ABS pump company in the industry. At the same time, the domestic water pump experts were solicited, and they were successfully developed through many improvements. After testing, all performance indicators have reached the advanced level of similar foreign products.

At present, QW submersible sewage pump products with a diameter of less than 150mm and a motor power of less than 15KW can be made with a new model, and there will be no overcurrent phenomenon when running at full head, and it can also be added on the basis of ordinary submersible sewage pumps. Mixing function and pump with cutting function with automatic mixing function we named it as automatic mixing submersible sewage pump, pump with cutting function we named it as cutting submersible sewage pump. All products can be used according to the needs of the shell can be used in stainless steel shell, the performance is more stable and the efficiency has improved by one level, and the entire body shape is more beautiful and generous. In addition, submersible sewage pumps with water leakage, electric leakage and overload protection functions can be customized according to requirements to prevent the common type QW sewage pump motor from being easily burned out.

Description of Pump Type

For example:150WQ160-15-15

150—The diameter of the outlet (mm)

WQ—W stands for " sewage ", Q stands for " Submersible "

QW—Moved submersible sewage pump

WQ—Fixed submersible sewage pump

160—Capacity

15—Head

15—Motor Power

Construction drawing

1. The unique single-piece or double-piece impeller structure greatly improves the dirt-passing ability, and can effectively pass the fiber material 5 times the diameter of the pump and the solid particles with a diameter of about 50% of the pump diameter.

2. The mechanical seal adopts a new hard and corrosion-resistant tungsten titanium material, which can make the pump run safely for more than 8000 hours.

3. The overall structure is compact, small in volume, low in noise, remarkable in energy saving, convenient in maintenance, no need to build a pump room, and can work when submerged in water, greatly reducing the project cost.

4. A high-precision anti-interference water leakage detection sensor is installed in the sealed oil chamber of the pump, and a thermosensitive element is pre-buried in the stator winding to automatically protect the pump motor.

5. Fully automatic control cabinet can be equipped according to user needs to automatically protect the pump from water leakage, leakage, overload and over-temperature, etc., which improves the safety and reliability of the product.

6. The float switch can automatically control the start and stop of the pump according to the change of the required liquid level, without the need for special care, and it is extremely convenient to use.

7. The WQ series can be equipped with a double rail automatic coupling installation system according to user needs, which brings greater convenience to installation and maintenance, and people do not have to enter the sewage pit for this.

8. Can be used within the full head, and ensure that the motor will not be overloaded.

9. There are two different installation methods, fixed automatic coupling installation system, mobile free installation.

Pump Supporting program and service application

1. The medium temperature does not exceed 60℃, and the medium weight is 1~1.3kg/dm3

2. For pumps without internal self-flowing circulating cooling system, the exposed liquid level of the motor part is less than 1/2.

3. The use range of cast iron material is PH5~9

4, 1Cr18Ni9Ti stainless steel material can use a variety of corrosive media.

Note: If the user has special requirements for temperature and medium, please indicate the details of the conveying medium when ordering, so that the unit can provide more reliable products.