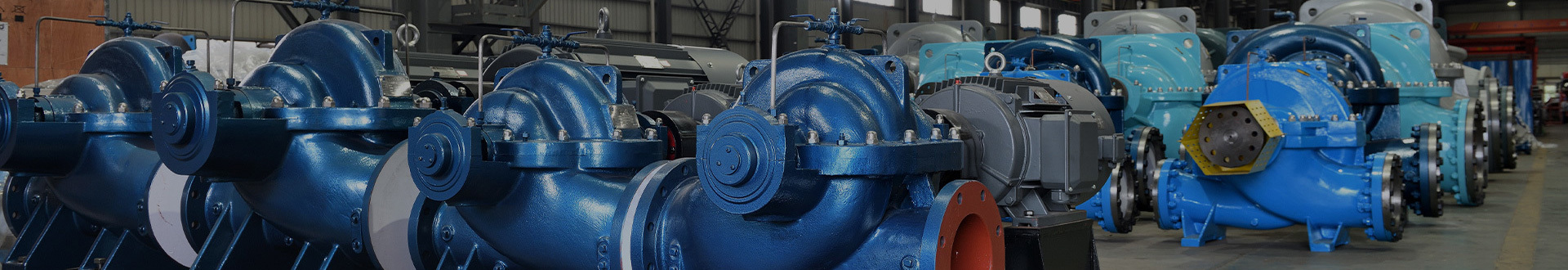

The ISG series single-stage single-suction vertical centrifugal pump is an excellent hydraulic model selected by the scientific and technical personnel of the unit and the United Nations water pump experts. The performance parameters of the IS type centrifugal pump are used to cleverly design on the basis of the general vertical pump. . At the same time, based on the use temperature, medium, etc., based on the ISG type, it dispatches suitable hot water, high temperature, corrosive chemical pumps, air conditioning cooling circulating water, oil pumps. This series of products has the advantages of high efficiency, energy saving, low noise and reliable performance.

1. Suction pressure≤1.0MPa, or maximum working pressure of the pump system≤1.6MPa, that is, pump suction pressure plus pump head≤1.6MPa, pump static pressure test pressure is 2.5MPa, please indicate the system work when ordering pressure. When the working pressure of the pump system is greater than 1.6MPa, it should be proposed separately when ordering, so that the over-current part and the connecting part of the pump are made of cast steel during manufacture (the highest pressure is 6Mpa).

2. Ambient temperature <40℃, relative humidity <95%.

3. The volume content of solid particles in the conveyed medium does not exceed 0.1% of the unit volume, and the particle size is less than 0.2 mm.

Note: If the medium used is with fine particles, please specify when ordering, so that the manufacturer uses a wear-resistant mechanical seal.

Main performance parameters

Capacity Q: 1.1~1080m3/h

Head H: 5~125m

Temperature -20-180℃

Suction pressure: 0-6MPa (please declare when higher than 0.4 MPa)

Description of Pump Type

For Example: ISG200-250I(A)

ISG——Single stage single suction centrifugal pump

200——Nominal diameter of pump inlet and outlet (mm)

250——Nominal diameter of impeller (mm)

I——Capacity classification

A——Cutting of the impeller for the first time

Outline Drawing

1. The pump has a vertical structure with the same inlet and outlet diameters, and is located on the same center line. It can be installed in the pipeline like a valve. It has a compact and beautiful appearance, a small area, and a low investment in construction. Can be used in outdoors.

2. The impeller is directly installed on the extended shaft of the motor. The axial size is short and the structure is compact. The pump and the motor bearing are configured reasonably, which can effectively balance the radial and axial loads generated by the pump operation, thereby ensuring the smooth operation of the pump. With low vibration and low noise.

3. The shaft seal adopts a mechanical seal or a combination of mechanical seals, an imported titanium alloy sealing ring, a medium-sized high temperature resistant mechanical seal and a hard alloy material, and a wear-resistant seal, which can effectively extend the service life of the mechanical seal.

4. Convenient installation and maintenance, no need to dismantle the pipe road system, as long as the nut of the pump conjoined seat is removed, all rotor components can be extracted.

5. The series and parallel operation modes of the pump can be adopted according to the usage requirements according to the capacity and head.

6. The vertical and horizontal installation of the pump can be used according to the requirements of pipeline layout.