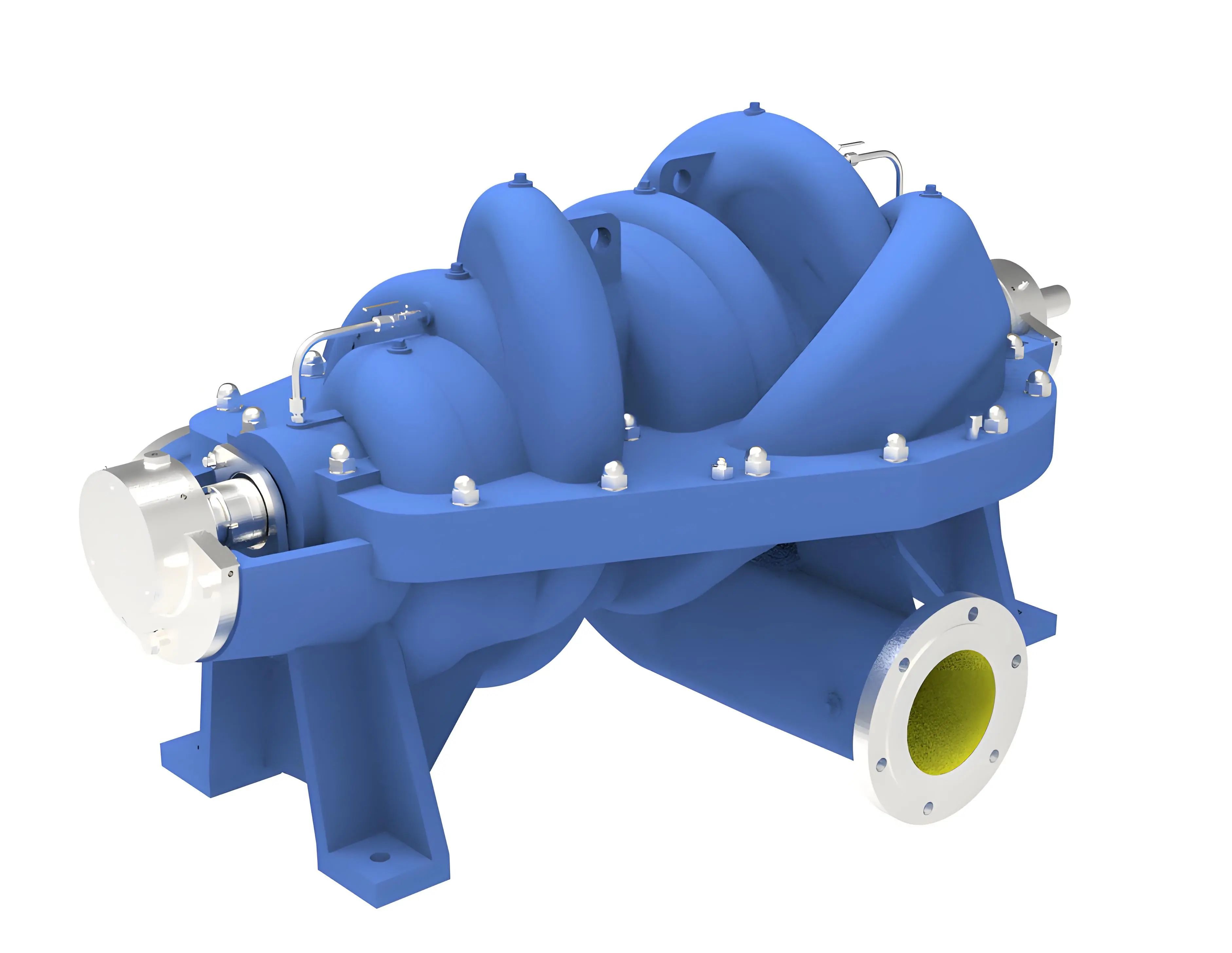

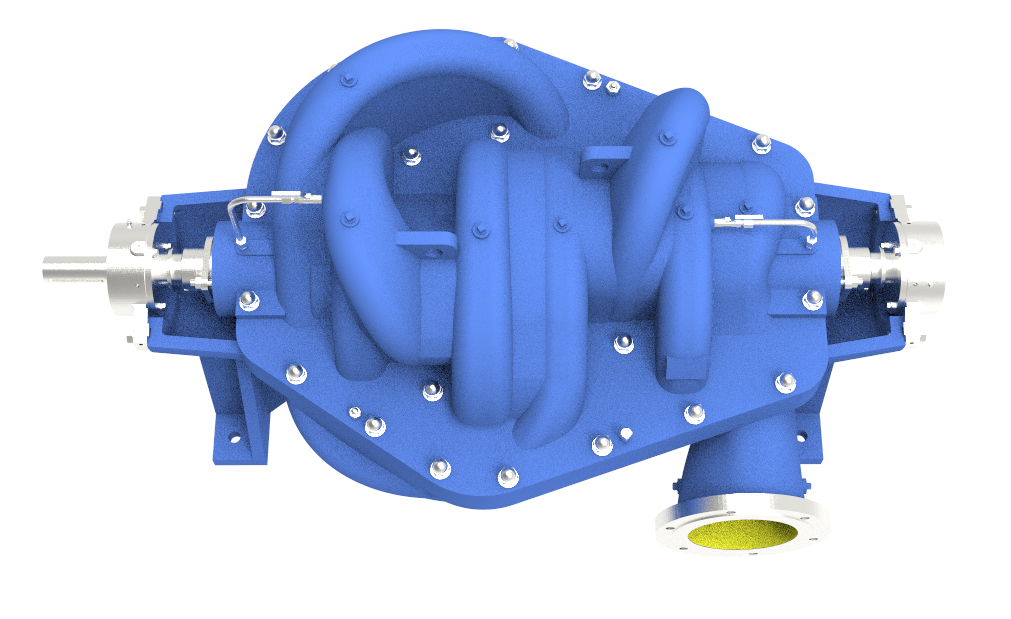

DS Series Split-Case Multistage Pump

Release time:

2025-07-22

Author:

Source:

DS Series Split-Case Multistage Pump

In the era of “dual carbon” goals, energy-efficient, safe, and reliable fluid handling equipment is essential to the success of large-scale engineering projects. Our independently developed DS Series Split-Case Multistage Pump combines advanced design, engineering innovation, and real-world performance. With proven success in national-level infrastructure and industrial projects, the DS Series is helping drive our high-end pump technology into broader global markets.

A High-Pressure Solution Engineered for Demanding Systems

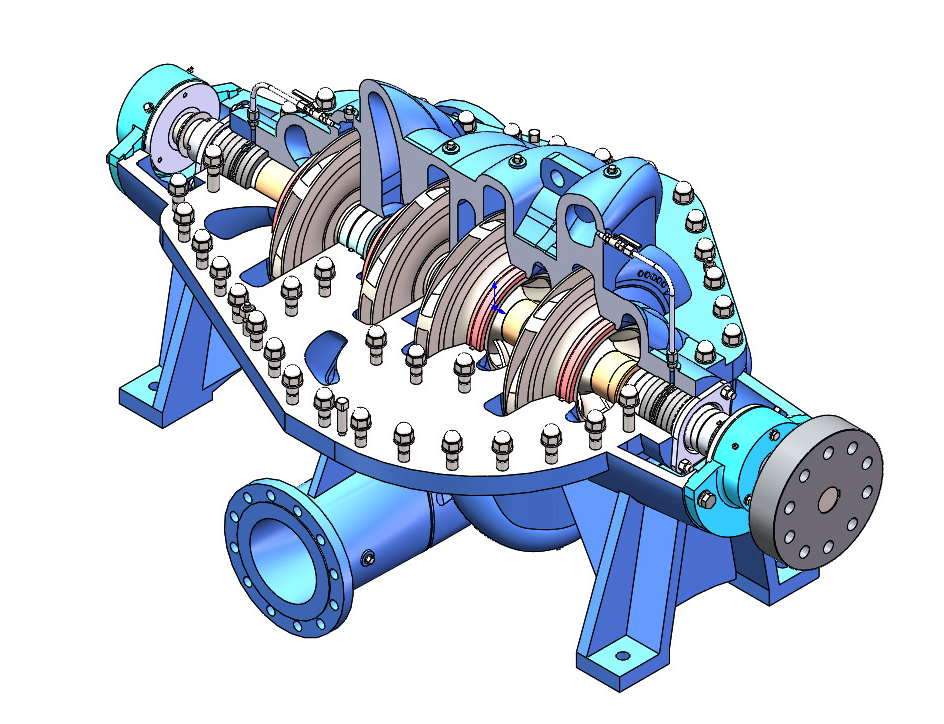

Backed by decades of experience in centrifugal pump technology, the DS Series was developed using CFD (Computational Fluid Dynamics) and FEA (Finite Element Analysis) to achieve optimized hydraulic performance and mechanical strength. Designed for high head, long-distance, and continuous-duty applications, the DS Series offers six major advantages:

Key Technical Advantages

1. Compact & Flexible Design

Optimized casing and internal structure eliminate unnecessary balance components—reducing size and simplifying layout in tight spaces, without compromising strength or reliability.

2. Smart Lubrication & Cooling

Built-in bearing lubrication and cooling circuits are designed for high-load, high-temperature environments, extending bearing life and reducing maintenance frequency.

3. Advanced Sealing System

A multi-stage sealing structure minimizes leakage between suction and discharge chambers. Shaft seals are positioned in low-pressure zones to improve reliability and protect sealing components.

4. Quick & Easy Maintenance

With side-mounted suction and discharge nozzles, the pump can be serviced by simply removing the upper casing—no need to disconnect the motor or piping—saving time and labor.

5. Precision Dynamic Balancing

Features include back-to-back impeller configuration, 180° offset keyways, and an elastic coupling—all working together to minimize axial force and radial deflection, ensuring smooth and stable operation.

6. Long-Term Reliability

Each rotor is dynamically balanced and the entire pump is validated through simulation and fatigue testing—ensuring 8,000+ hours of continuous operation in the most demanding environments.

Versatile Applications Across Industries

With wide-ranging parameters and robust performance, the DS Series is ideal for systems requiring high flow and pressure, including:

✅ Water Resources

Long-distance water transfer

Inter-basin diversion

Irrigation and reservoir supply

Flood control and drainage

✅ Petrochemical Industry

Crude oil transport

Circulation of process liquids

Transfer of high-temp and high-pressure fluids

✅ Power Plants

Boiler feedwater systems

Cooling water loops

Demineralized water return

✅ Municipal Infrastructure

Urban water supply trunk lines

Sewage transfer and treatment

Pump station upgrades

✅ Mining and Mineral Processing

Mine dewatering

Slurry transfer

Wear-resistant for high solid content

Engineered for Efficiency. Built for Reliability. Trusted in Mission-Critical Projects.

The DS Series Split-Case Multistage Pump is not just a product—it’s a high-performance solution tailored for the toughest environments and the most important infrastructure systems.

Recommended Reading

Why Choose a Horizontal Split-Case Pump as a Fire Pump?

2025-12-02