PRODUCTS

XSL vertical split case pump

● Pump outlet diameter Dn: 80~900mm

● Capacity Q: 22~16236m3/h

● Head H: 7~300m

● Temperature T: -20℃~200℃

● Solid parameter ≤80mg/L

● Permissible pressure ≤5Mpa

XSL type pump is a new generation of high performance single-stage double-suction centrifugal split pumps. They are mainly used in delivering liquids of the water plant, airconditioner circulation water, heating pipe network system, building water supply, irrigation and drainage of pump stations, power plants, industrial water supply system, fire protection, ships industry and mine. It is a new substitute of SH, S, SA, SLA and SAP.

|

Main performance parameters ● Pump outlet diameter Dn: 80~900mm ● Capacity Q: 22~16236m3/h ● Head H: 7~300m ● Temperature T: -20℃~200℃ ● Solid parameter ≤80mg/L ● Permissible pressure ≤5Mpa

|

Description of Pump Type ● For example:XSL 250-450A-L(R)-J ● XS: advanced type split centrifugal pump ● 250:pump outlet diameter ● 450:standard impeller diameter ● A: Changed outer diameter of impeller (the max diameter without mark) ● L: vertical mount ● R: heating water ● J: Pump speed changed(Maintain the speed without mark) |

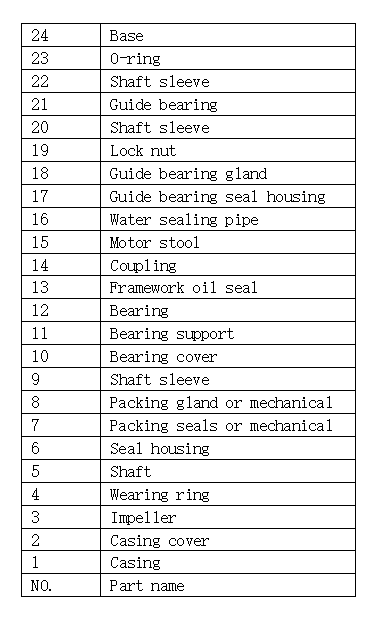

Pump Supporting program

|

Item |

Pump Supporting program A |

Pump Supporting program Q |

Pump Supporting program B |

Pump Supporting program S |

|||

|

1 |

2 |

1 |

2 |

3 |

|||

|

Pump casing |

Grey cast iron |

Ductile cast iron |

Ductile cast iron |

Extra low carbon stainless steel |

Ni-Cr chromiumcast iron |

Ductile cast iron |

Stainless steel |

|

Impeller |

Grey casting iron |

Cast steel |

Stainless steel |

Duplex S.S. |

Tin bronze |

Tin bronze |

Tin bronze |

|

Shaft |

#45 steel |

#45 steel |

Stainless steel |

Duplex S.S. |

2Crl3 |

2Crl3 |

2Crl3 |

|

Shaft sleeve |

#45 steel |

#45 steel |

Stainless steel |

Extra low carbon stainless steel |

lCrl8Ni9Ti |

lCrl8Ni9Ti |

lCrl8Ni9Ti |

|

Wear ring |

Grey casting iron |

Cast steel |

Cast steel |

Duplex S.S. |

Tin bronze |

Tin bronze |

Tin bronze |

|

Services |

For pure water and lower strength applications |

For pure water high strength applications |

For media with more solid impurities PH<6 chemical corrosion and for high strength applications |

The sea water pump |

|||

|

These configurations are recommended by the manufacturer, customers could change their materials according to specific needs. |

|||||||

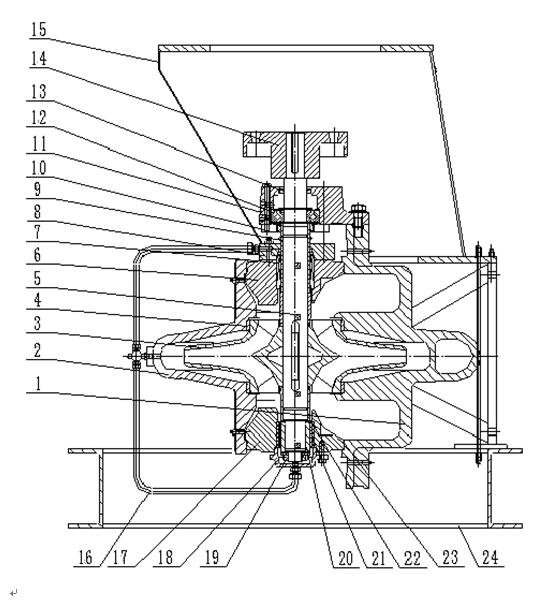

XS-L vertical structure

|

|

Add: Jiuhua Industiral Park,Xiangtan City,Hunan Province,China

Call us:+86-0731-55599916

+86-18673110460

Email:export@mwpump.com

Hunan M&W Pump Co., Ltd 湘ICP备14003804号-2 www.300.cn Manager